Quartz sand, also known as silica sand. After silica sand beneficiation and purification, it will become high-purity quartz sand. Silica sand has wide applications in glass, ceramics, metallurgy, casting, and refractory materials industries. At present, the quartz sand beneficiation process involves removing mineral impurities from the raw quartz sand through scrubbing, desliming, magnetic separation, spiral chute gravity separation, flotation, acid washing, or a combination of several methods to obtain high-purity quartz sand with satisfactory particle size and impurity content. In the beneficiation process, the mining method for quartz sand beneficiation include magnetic separation, flotation separation, gravity separation, etc. Before silica sand is put into the processing in the beneficiation production line, there will conduct several beneficiation experiments to test which method is the best to achieve good benefits. So, what equipment is suitable for silica sand beneficiation experiments?

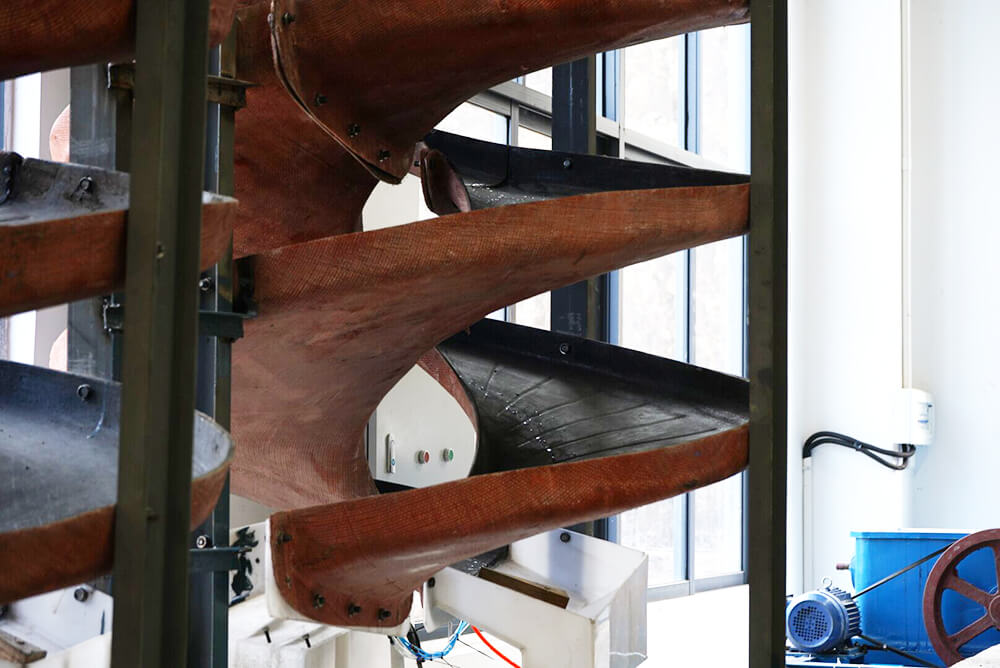

1. Laboratory Spiral Chute

The spiral chute is a gravity beneficiation equipment used for separating minerals with sufficient specific gravity differences, with the aim of gravity separation of materials. Laboratory spiral chutes are smaller than ordinary spiral chutes and are suitable for indoor beneficiation experiments. The small lab spiral chute is gravity beneficiation equipment used in universities, research institutes, and beneficiation plants to conduct ore beneficiation research and experiments. Their beneficiation effect is not much different from that of large-sized spiral chutes.

The applicable minerals for laboratory spiral chutes are tantalum, niobium, tin, tungsten, titanium, iron, and other minerals with sufficient specific gravity differences. All the minerals achieve an ideal selection effect.

- Operation:

Prepare the slurry and pour the slurry into the distribution bucket and add supplementary water to adjust the slurry concentration. The slurry naturally swirls from high to low, generating an inertial centrifugal force in the rotating inclined flow rate. Due to differences in the specific gravity, particle size, and shape of the ore, the gravity and centrifugal force of the swirling flow will separate the ore and sand. The concentrate will flow into the concentrate bucket and pipe out, while the middlings and tailings will flow respectively into the middlings and tailings bucket, and pump to the slurry tank. - Advantages:

1. Stable performance for separation process, and clear mineral ore separation.

2. Simple structure, small land scale, easy installation and operation.

3. Large processing capacity, no need for power, large processing capacity, and low investment cost.

4. High beneficiation enrichment ratio, and high recovery rate.

5. Lightweight, moisture-proof, rust-proof, and corrosion-resistant.

2. Laboratory Flotation Machine

The laboratory flotation machine is for industrial experiments such as coal, electricity, mining, geology, chemistry, metallurgy, building materials, and chemical industry to flotation small amounts of ore samples. In the silica sand experiment, if there are a lot of non-magnetic associated minerals such as feldspar and mica in quartz sand, a flotation machine can remove them. The flotation machine is for separating materials (the quartz sand beneficiation equipment used in this process is various types of stirring flotation machines. The stirring flotation machine divides into suction mechanical stirring flotation machines and inflatable mechanical stirring flotation machines). The laboratory flotation machine requires the addition of conventional reagents. Different chemicals handle different materials. The applicable minerals of the laboratory flotation machine are gold, copper, lead zinc, fluorite, lithium ore, etc.

- Operation:

Pour the prepared slurry into the tank and dilute it with water to the desired concentration; Start the motor and add an appropriate amount of flotation agent according to the experimental requirements; When the foam generates in the tank, turn on the switch of the scraper part to start flotation; After reaching the specified flotation time, turn off the motor to stop the impeller and scraper from running; - Advantage

1. The main shaft is made of stainless steel, which is acid and corrosion-resistant. The impeller cover plate is made of medium-hard acid-resistant rubber.

2. The material of the flotation cell is an organic glass cell.

3. The scraper belt is made of cowhide and is not broken easily.

4. Fine aircraft, neat appearance, and even spray paint. Low price and easy to maintain, and requires a small land scale.

3. High Gradient Magnetic Separator

The high gradient magnetic separator equipment is suitable for the separation of weak magnetic minerals, such as hematite, limonite, siderite, manganese ore, ilmenite, wolframite, and other weakly magnetic metal minerals through wet separation, as well as the separation of black and white tungsten and tungsten tin. It is also suitable for purifying non-metallic minerals such as quartz, feldspar, nepheline, kaolin, and other iron removal. For quartz sand containing iron impurities, magnetic separation is one of the effective methods for removing impurity substances, which can remove weak magnetic impurities such as hematite, limonite, and biotite, including contiguous particles, as much as possible. The magnetic separation method usually uses wet high-intensity magnetic separators or high-gradient magnetic separators.

- Operation

Pour the prepared material into a high-gradient magnetic separator, with a particle size of 0-1.2mm. It generates an induced magnetic field in the sorting area and a high gradient magnetic field on the surface of the magnetic medium located in the sorting area; The rotating ring rotates clockwise to continuously feed and transport the magnetic medium out of the sorting area; The slurry is fed into the ore hopper and flows through the rotating ring along the gap of the upper iron yoke. The magnetic particles in the slurry are adsorbed on the surface of the magnetic medium rod, transported by a rotating ring to the top non-magnetic field area, and washed into the concentrate hopper by flushing water. Non-magnetic particles pass through the magnetic medium pile under the gravity and pulsating fluid force and separate from the magnetic particles. Then it flows into the tailings hopper along the gap of the lower iron yoke for discharge. - Advantage

1. High enrichment ratio and high recovery rate.

2. Reliable operation and strong adaptability to wave motion in feeding particle size, concentration, and grade.

3. Strong processing ability and good sorting effect.

The above machines are the equipment used for the silica sand separation process. According to the different properties of silica sand, it will use corresponding mining equipment. JXSC lab mineral ore processing equipment manufacturer provides various laboratory experimental equipment, lab crushing machines, grinding machines, gravity separator machine, flotation machine, magnetic separator machine, etc. Besides, we also provide various mineral ore testing services to confirm the best mineral processing method for the mineral processing plant. If there are any questions about mining processing, come to inquire and get professional suggestions!