what is it

Laboratory Double-Roll Crusher

Popular Models: The 911MPERC8C laboratory hammer crusher minimizes overbreakage.

Capacity: 100-500kg/hr

Application:It is widely used in laboratory research in mining, metallurgy, chemical industry and other fields to crush and reduce the size of medium-hard materials.

Description

Laboratory roll crushers, also known as laboratory double roll crushers, mainly crush materials into smaller particles or powders. Commonly used in laboratories or small batch production lines, including ore, rock, coal, ore sand and other materials crushing. With its high efficiency, adjustable and widely applicable features, the lab roll crusher has become one of the most commonly used equipment in laboratory sample preparation. In addition, the finished product provided by its crusher has a uniform particle size, which can ensure the accuracy and reliability of experiments and analysis. When using a lab roll crusher, it is necessary to adjust the rollers’ spacing and rotation speed according to the sample’s nature and the required degree of crushing to obtain the best crushing effect.

Advantages

High-efficiency crushing

The surface of the double rollers is designed with high pressure, which increases the effect of extrusion and crushing of materials and can meet the experimental needs of different customers.

Adjustable particle size

During the crushing process, the rollers’ gap size and rotating speed can be adjusted to control the final crushed particle size of the material.

Low Noise

Our laboratory roll crusher operates with relatively low noise, which helps improve the laboratory’s working environment.

Uniform finished product

Since the material is bidirectionally squeezed and crushed between the two rollers, the particle size distribution of the obtained crushed material is relatively uniform.

Principle

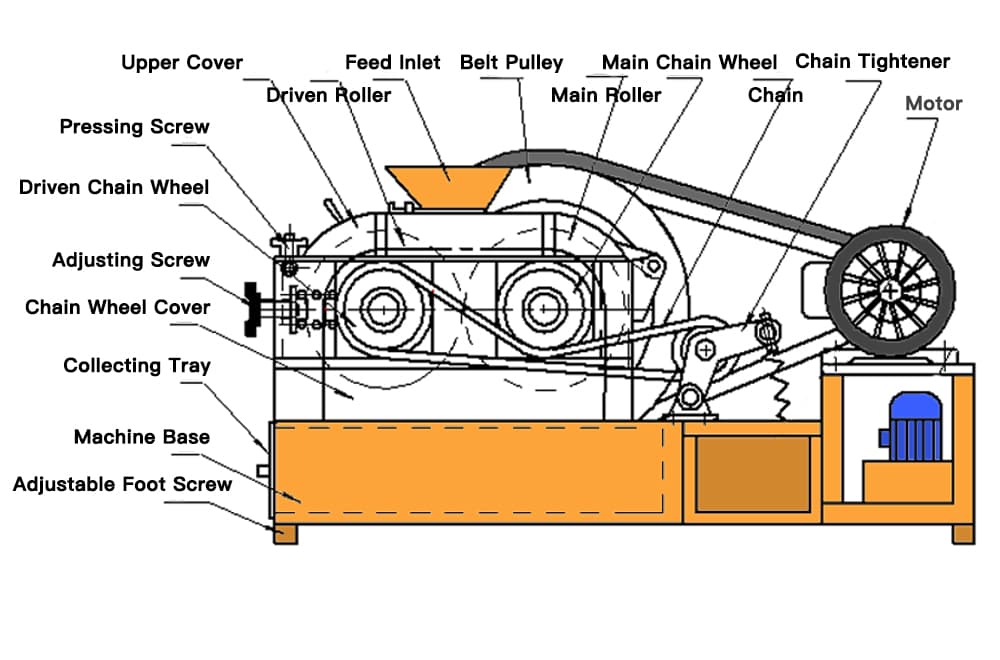

The laboratory roll crusher mainly comprises two parallel rotating rollers with a certain gap between them, through which the material is crushed. The material enters the feed port of the lab roll crusher through the feeding device, enters the crushing area between the rollers, and the rollers start to rotate. The material is clamped between the rollers, and due to the rotation and mutual extrusion of the rollers, the material sample is gradually crushed into smaller particles or lumps. The crushed material falls under the rollers and is collected through the outlet, where it can be further analyzed or processed.

Specification

| Model | Roll Size (mm) | Max.Feeding Size (mm) | Discharge Size(mm) | Capacity (kg/hr) | Roll Rotation Rate (r/min) | Dimensions (mm) | Motor Power (kW) | Wght(kg) |

| XPC200×75 | Φ200×75 | ≤13 | ≤1 | 100 | 320 | 1000×500×650 | 1.5 | 260 |

| XPC200×100 | Φ200×100 | 200 | 1000×500×650 | 2.2 | 300 | |||

| XPC200×125 | Φ200×125 | 250 | 1000×500×650 | 3 | 375 | |||

| XPC200×150 | Φ200×150 | 500 | 1000×500×650 | 4 | 400 |