Manganese is an essential material in the steel industry, accounting for 90% -95% of its usage. It is mainly used as a deoxidizer and desulfurizer in ironmaking and steel-making processes, as well as in the manufacturing of alloys. Common manganese ores include oxidized manganese ore and manganese carbonate ore. The beneficiation method of manganese oxide ore is gravity separation. The gravity separation method is suitable for selecting manganese ores with coarse particle size with simple structures, especially oxidized manganese ores with high density. When using the gravity separation method to treat manganese oxide ore, the ore is crushed to around 6-10mm before sorting. The coarse material goes to a wave-type jig separator for separation, and fine-grade material uses a shaking table or spiral chute for selection, often using a 6s-type shaking table. Sometimes, the overflow of ore washing also requires further recovery by gravity separation or strong-magnetic separation.

With the maturity of beneficiation technology, more and more people are joining the business of manganese ore mining. Before mining, it is necessary to conduct beneficiation experiments to determine which beneficiation method is most suitable for the ore property. How does the manganese ore experiment process? What equipment is for the experimental laboratory testing?

Lab Crushing Equipment

For some large-size manganese ore, there is a lab jaw crusher for crushing the raw ore to a certain particle size and sometimes will need a secondary crusher to process the stone to the required particle size. The lab jaw crusher is for first crushing after it is a lab hammer crusher or a double roller crusher.

Lab Jaw Crusher

- Introduction: It is the primary process of crushing large pieces of material into small particles.

- Application: A lab jaw crusher is often used in various mineral ores crushing in the mineral processing industry and lab experiments.

- Applicable materials: rock gold, copper ore, manganese ore, and various stones, etc

- Testing Process: Put 100mm manganese rock ore into the jaw crusher from the feeding port, and after starting the machine, the two teeth press against each other, breaking the material into small particles and crushing them to 20-30mm, and then discharge them from the discharge port.

Gravity Separation Equipment

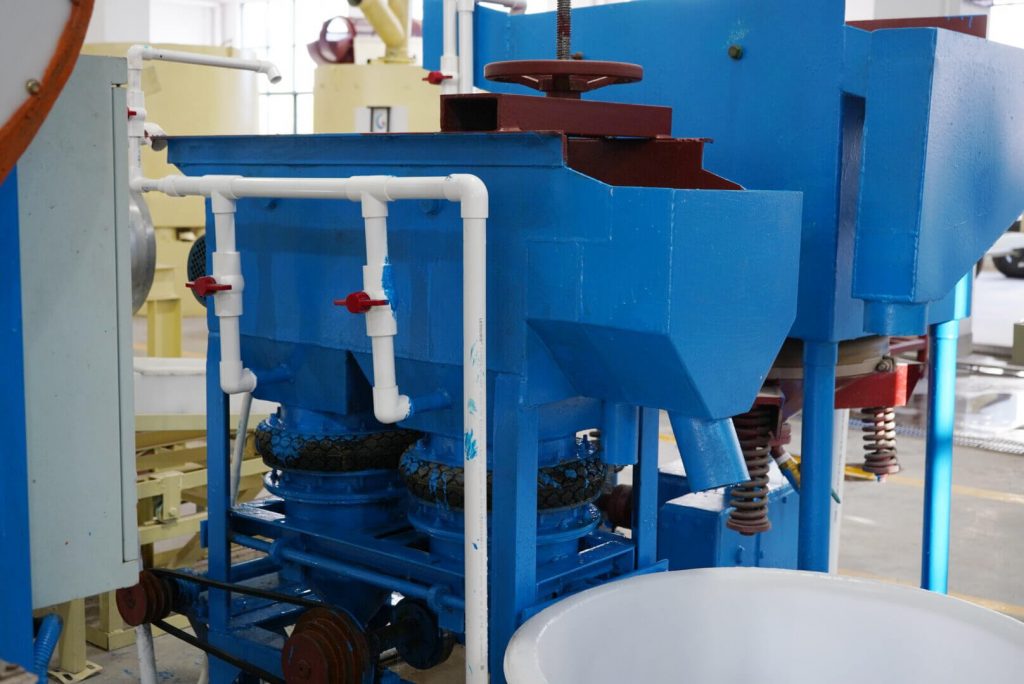

The gravity beneficiation equipment for manganese ore is a jig separator and sometimes uses a shaking table. However, due to the inability of the selected particle size and processing capacity of the shaking table that didn’t meet the requirements for large-scale production, jig separators are popular in manganese ore gravity beneficiation. Especially with the successful introduction of large particle jigs, the application of gravity beneficiation for manganese ore has become more widespread. A jigging machine is a beneficiation equipment that uses the difference in specific gravity (density) between minerals and waste rocks for separation. It has the advantages of high efficiency, energy conservation, environmental protection, large beneficiation particle size, and wide beneficiation particle size.

1. Lab Jig Machine

- Introduction: Using Gravity Separation to Collect Manganese Concentrate.

- Application: Various mineral processing equipment, such as gold, diamond, tantalum niobium tin, manganese ore, heavy gold ore, etc

- Process: Put 0-30mm manganese ore into the jig machine, and the sawtooth wave first rises in a straight line, then decreases, and repeatedly circulates. It uses water as the beneficiation medium and sorts according to the specific gravity difference between manganese ore and gangue. A short period of processing to get manganese concentrate.

Advantages

- Compact structure, small land space, and large processing capacity. The JT series serrated wave jig machine adopts a downward-moving transmission structure, and the equipment structure of the serrated wave jig machine is more compact, with a large processing capacity.

- It adopts a cam mechanism for transmission, the serrated waveform pulse curve generated by the jig results in an average upward water flow and a rapid downward water flow, effectively improving the recovery rate of minerals in fine-grained materials, and achieving excellent beneficiation results for fine-grained materials.

- It has the characteristics of water-saving and continuous operation.

- Stroke and stroke adjustment are convenient, and installation and maintenance are simple.

2. Lab Shaking Table

The lab shaking table is for sorting fine-grained materials and is one of the most commonly used gravity beneficiation equipment in mineral processing operations. It is usually equipped with other equipment to recover 0-2mm fine-grained minerals during mineral processing. It is popular in industrial and semi-industrial production, and mineral processing experiments for separating rare and precious metals such as tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, gold, etc. It can also process coal mines. It is suitable for different operations such as rough selection, concentrating, and scavenging, selecting different particle sizes such as coarse sand (2-0.5mm), fine sand (0.5-0.074mm), and mineral (-0.074).

- Application: It is mainly for separating rare and precious metal ores such as gold, silver, copper, lead zinc, tantalum niobium tin, iron, manganese, etc.

- Testing Process: Place 0-2mm manganese ore into a shaking table. By utilizing mechanical shaking and the flushing effect of water flow, the mineral particles will separate according to their density, and obtain Multiple products simultaneously, and the minerals zone on the bed surface is clear.

Advantages

- The selection process is stable and easy to control;

- The allowable variation range of ore concentration is big, with a high enrichment ratio and recovery rate;

- Small land occupation, low water consumption, simple structure, no need for power, and large processing capacity;

- Easy to install, easy to operate, with low investment and quick return.

Magnetic Separation Equipment

The magnetic beneficiation process of manganese oxide ore mainly uses a strong magnetic separator to perform magnetic beneficiation on medium and fine-grained manganese ore, which is suitable for medium and fine-grained embedded manganese oxide ore. The magnetic separator has a good effect on the magnetic beneficiation of manganese ore, hematite, and limonite. This machine comes with a vibrating feeder to ensure uniform feeding. The sorting belt is a high wear-resistant ultra-thin belt, and the magnetic pole has advantages like waterproofing and rust prevention.

Wet drum magnetic separator

- The lab wet drum magnetic separator is for selecting weak-magnetic minerals, which has a strong adsorption effect on weak-magnetic minerals and has good results.

- Application: It is mainly for separating weak-magnetic minerals such as hematite, titanium ore, manganese ore, etc

- Testing Process: Pump 0-2 manganese concentrate into a strong-magnetic separator with a magnetic field strength of 8000-13000 Gauss and two ore discharge ports. One port is the selected weakly magnetic minerals, mainly manganese ore. One is the tailings on the other port.

Advantages

- Good separating effect and high sorting grade.

- Large processing capacity and high recovery rate.

- High magnetic field coefficient and big magnetic permeability depth.

- The magnetic separator has a long service life, a low demagnetization rate, and needs less maintenance.

Manganese ore has other forms of existence, and manganese oxide ore will need trommel drum washing machines for washing, and multi-metal composite manganese ore will need flotation machines, vibrating screens, etc. When selecting beneficiation equipment, it is necessary to choose the corresponding equipment according to the characteristics of the ore for beneficiation. JXSC lab mineral processing equipment manufacturer has more than 38 years of experience in mining processing, and we provide service for mining processing testing and suggestions for process flow. There is laboratory equipment for processing minerals such as gold, tin, tungsten, lead, zinc, tantalum, niobium, iron, manganese, silver, titanium-iron, etc. Lab machines include laboratory jaw crusher, hammer crusher, roller crusher, grinding equipment, mineral separating equipment, screening, washing equipment, etc. Welcome to consult if you are interested in it!